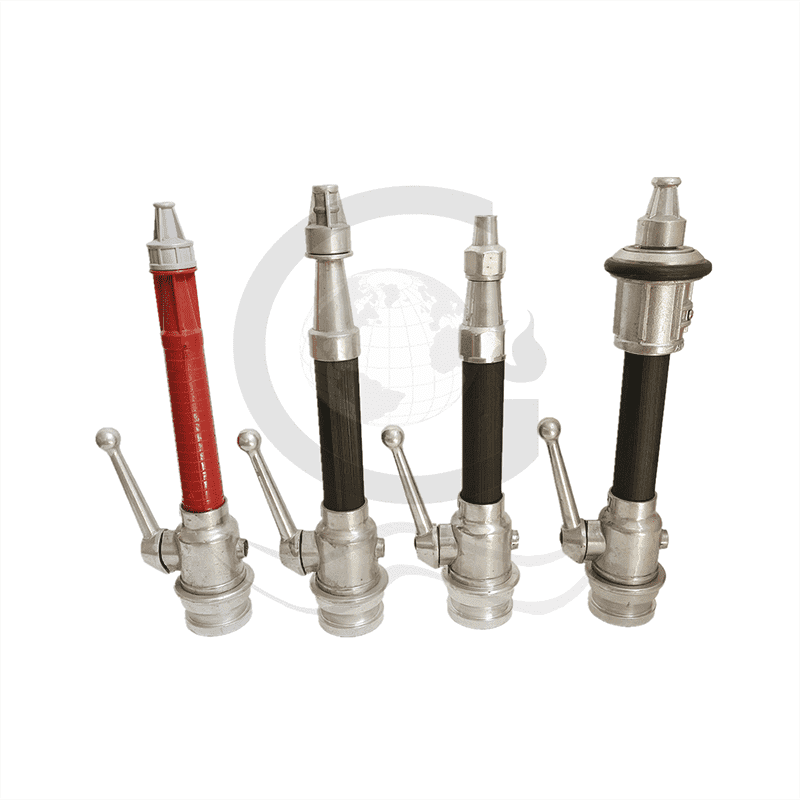

Ukugcinwa kahle kwe-Jet spray nozzle nge-valve yokulawula kuqinisekisa ukusebenza okuthembekile. Ukuhlanza njalo, ukuhlola, nokusebenza ngendlela efanele kunciphisa ama-clogs nokuguga. Ucwaningo lukhombisa ukuthi lezi zinyathelo zinweba ubude bempilo yeI-Fire Jet Spray Nozzle, I-Brass Jet Spray Nozzle, futhiI-Full Cone Jet Spray Nozzles, ukuvimbela ukwehluleka kanye nokusekela amaphethini okufuthwa angaguquki.

Ukuhlanza Okuvamile Nokuhlolwa Kwe-Jet Spray Nozzle eneValve Yokulawula

Izinqubo Zokuhlanza

Ukuhlanza okujwayelekile kugcinaJet spray nozzlenge-valve yokulawula esebenza kahle. Ukungcola, udoti, kanye namadiphozithi amaminerali kungavimba umlomo wombhobho futhi kunciphise ukugeleza kwamanzi. Izicishamlilo namaqembu okulungisa asebenzisa lezi zinyathelo ukuhlanza umlomo:

- Susa i-nozzle ekuxhumekeni kwepayipi.

- Hlanza ingaphandle ngamanzi ahlanzekile ukuze ugeze izinhlayiya ezixegayo.

- Sebenzisa ibhulashi elithambile ukukhuhla umzimba we-nozzle kanye ne-outlet.

- Hlola i-valve yokulawula noma yiziphi izinhlayiya ezinamathele.

- Geza ingaphakathi ngamanzi ukuze usule noma yikuphi ukwakheka kwangaphakathi.

- Yomisa umlomo ngendwangu ehlanzekile ngaphambi kokuhlanganisa futhi.

Ithiphu:Ukuhlanza njalo kuvimbela ama-clogs futhi kuqinisekisa iphethini yesifutho engashintshi phakathi nezimo eziphuthumayo.

Ukuhlanza i-Jet spray nozzle nge-valve yokulawula ngemva kokusetshenziswa ngakunye kusiza ukugcina ukusebenza kwayo. Amaqembu kufanele agweme ukusebenzisa amakhemikhali anokhahlo angase alimaze umzimba we-aluminium noma izingxenye zangaphakathi.

Ukuhlolwa Kokugqoka Nokulimala

Ukuhlola kusiza ukuhlonza izinkinga ngaphambi kokuba zithinte imisebenzi yokucisha umlilo. Amaqembu abheka izimpawu zokuguga nokulimala okungaba nomthelela kwikhwalithi yesifutho nokuphepha kwemishini. Izinkinga ezijwayelekile zihlanganisa:

- Ukuvinjwa yimfucumfucu

- Ukugqokwa kweziphethu

- Ukwakhiwa noma ukuguguleka kwe-magnetite noma ezinye izinhlayiya ezindaweni ezibucayi zesifutho

Lezi zinkinga zingabangela isifutho esingafanele, izinga eliphansi le-steam, nokuguguleka kwamapayipi. Ukulimala kungase futhi kuthinte imishini engaphansi komfula futhi kunciphise umthamo wesifutho. Ukungazinaki lezi zimpawu kungaholela ekuqhekekeni kwezindololwane, amashubhu anwetshiwe, noma ngisho nokuhluleka kweshubhu.

Ukutholwa kusenesikhathi ukuguga ku-Jet spray nozzle nge-valve yokulawula kunciphisa izindleko zokulungisa futhi kuvimbela ukulahleka kokusebenza kahle kokukhiqiza. Ithebula elingezansi libonisa ukuthi ukutholwa kusenesikhathi kanye nokulawula okunembayo kwesabelomali sokulondoloza inzuzo:

| Isici | Incazelo |

|---|---|

| Uhlelo lufakiwe | Isistimu yokufutha ezenzakalelayo enezimbobo ze-hydraulic PulsaJet® kanye ne-AutoJet® Spray Control Panel |

| Umphumela Wezindleko Zokulungisa | Ukwehliswa okukhulu ngenxa yokuqedwa kwenkungu nokufutha ngokweqile |

| Isicelo sokuthambisa | Ukulawula ivolumu okunembile ngokulungiswa okuzenzakalelayo kwesivinini somugqa nobubanzi bomugqa |

| Imanuwali vs Ukulawula Okuzenzakalelayo | Ama-valve enaliti enziwe ngezandla alungiswa ngama-opharetha aholele ekuhlanganiseni okungalingani namakhoyili anqatshiwe; isistimu ezenzakalelayo iqinisekisa ukumbozwa okufanayo |

| Izinzuzo Zokusebenza | Imvamisa yesifutho engaguquki kanye nomjikelezo womsebenzi kugcina usayizi wokuwa olungile kanye ne-engeli yesifutho naphezu kokuguquguquka kwesivinini somugqa |

| Umthelela Wezezimali | Izindleko zesistimu zibuyiselwe emasontweni amabili; ukonga kwanyanga zonke kwe-€20,000 kuya ku-€30,000; ukonga konyaka ngaphezulu kwama-€240,000 |

| Umthelela Wokutholwa Kwempahla Yangaphambi kwesikhathi | Ukulawula okuthuthukisiwe nokwenza okuzenzakalelayo kusho ukuthi ukutholwa kusenesikhathi kokugqokwa kwenozzle kusiza ukugcina lezi zinzuzo ngokuvikela isifutho esingalingani kanye ne-overspray, ngaleyo ndlela kunciphisa izindleko zokuyilungisa. |

Ukuhlola njalo nokuhlanzwa kwe-Jet spray nozzle nge-valve yokulawula kusiza amaqembu agweme ukulungiswa okumba eqolo nokugcinaizinhlelo zokuvikela umliloisilungele isenzo.

Ukusebenza Okufanelekile Nokugcinwa Kokuvikela Kwe-Jet Spray Nozzle eneValve Yokulawula

Ukusetshenziswa Okulungile Kwevalvu Yokulawula

Ama-opharetha kufanele aphathe i-valve yokulawula ngokucophelela ukuze balondoloze ukusebenza kwe-Jet spray nozzlenge-valve yokulawula. Ukusebenzisa i-valve endaweniingcindezi efaneleiqinisekisa iphethini yesifutho engashintshi kanye nokugeleza kwamanzi ngendlela efanele. Uma ingcindezi yehla kakhulu, isifutho siba ngokungalingani futhi singasebenzi kahle. Ukucindezela okuphezulu kungagugisa umlomo wombhobho ngokushesha futhi kushintshe usayizi wamaconsi, kwenze isifutho singabi nomfaniswano.

Ukuqinisa ngokweqile ukupakishwa kwe-valve kungabangela ukuthi i-valve inamathele, okwenza kube nzima ukusebenza. Ukuqiniswa kancane kungaholela ekuvuzeni, okumosha amanzi futhi kunciphise ukusebenza kahle. Amaqembu okunakekela kufanele alungise amantongomane okupakisha ngokucophelela futhi agcobe ngokufanele. Ukuqeqesha abasebenzi ngokuphatha ama-valve ngendlela efanele kuyasiza ekuvimbeleni lezi zinkinga.

Ithiphu:Hlanza njalo ama-clogs ngakolunye uhlangothi lokugeleza kwesifutho ukuze ugweme ukuphusha imfucumfucu ijule ku-nozzle.

Isheduli Yesondlo kanye Nohlu Lokuhlola

Isheduli yokulungisa ejwayelekile igcina i-Jet spray nozzle enevalvu yokulawula ithembekile. Amaqembu kufanele alandele lezi zinyathelo:

- Hlola amapayipi, imibhobho, nezixhumi nsuku zonke ukuze uthole ukuvuza noma umonakalo.

- Hlanza futhi ufake ama-nozzles njengoba kudingeka ukuze uvimbele ama-clogs.

- Hlola isibhamu sokuqhumisa kanye nenduku ukuze usebenze kahle.

- Hlola futhi uhlanze izisefo zokungena emanzini ukuze uqinisekise ukutholakala kwamanzi ahlanzekile.

- Gcoba ama-valve okulawula ukuze uwagcine esebenza kahle.

- Linganisa amageji okucindezela ukuze ufunde okunembile.

- Hlanza ingaphandle namaphaneli okulawula ukuze uvimbele ukunqwabelana kwemfucumfucu.

| Isici Sokulungisa | Isincomo |

|---|---|

| Isondlo Sesizini | Flush imigqa entwasahlobo; hlanza futhi ugcine ekwindla |

| Ukuhlanza Umjikelezo | Gcoba imibhobho, xubha ngobumnene, hlambulula bese ufaka kabusha |

| Izinyathelo Zokuvimbela | Sebenzisa izihlungi, ama-valve okukhipha amanzi, futhi wandise ukuhlanza ezindaweni ezinamanzi aqinile |

Ukulandela lolu hlu lokuhlola kusiza ukuvimbela ama-clog, ukuvuza, nezinkinga zephethini yesifutho, okusekela ukuvikelwa komlilo okuthembekile.

Amathiphu okuxazulula izinkinga kanye nesitoreji se-Jet Spray Nozzle eneValve Yokulawula

Ukulungisa Ama-Clog, Ukuvuza, kanye Nezinkinga Zephethini Yesifutho

Amathimba okunakekela ngokuvamile ahlangabezana nokuxhunywa, ukuvuza, nezinkinga zephethini yokufutha ngemibhobho ye-jet spray. Lezi zinkinga zinganciphisa ukukhiqiza futhi zikhuphule izindleko. Izinyathelo ezijwayelekile zokuxazulula inkinga zifaka:

- Imilomo exhunyiwe ivamise ukukhombisa ukugeleza okuncishisiwe noma isifutho esingalingani. Amaqembu ahlonza indawo evalekile ngokubheka umbhobho, i-lance, noma isistimu yepayipi. Babona izimpawu ezinjengokuconsa noma ukuyeka ngokuphelele.

- Ukuphepha kuza kuqala. Ochwepheshe bavala isistimu, bagqoke amagilavu nezibuko, futhi bavumele okokusebenza ukuthi kuphole ngaphambi kokuhlanza.

- Amathuluzi okuhlanza afana namabhulashi, okokukhetha, nezinyibilikisi ezihambisanayo kusiza ukususa izinsalela. Ukucwilisa umlomo wombhobho okungenani imizuzu engama-45 kuncibilikisa ukuvinjwa okunenkani.

- Ukuvuza kuvame ukuvela kuma-gasket seal noma ekuxhumekeni kwamapayipi. Ukuhlola lawa maphuzu, ukuqinisa amantongomane okukhiya, nokusebenzisa izivivinyo zikadayi kusiza ukuthola lapho kuvuza khona. Ukusebenzisa i-silicone sealant noma ukufaka izingxenye ezigugile kubuyisela ukusebenza okufanele.

- Izinkinga zephethini yokufutha zingase zibe umphumela wokuguguleka, ukugqwala, noma ukuhlangana okungafanele. Ukuhlanza njalo, ukusetshenziswa kwezihlungi, nokuhlolwa komonakalo kugcina isifutho esingaguquki.

Ithiphu:Ukuhlanza okusebenzayo nokuhlola kuvimbela iphethini yesifutho nezinkinga zokuvuza.

Izinyathelo Zokuqaphela Isitoreji Nokuphatha

Isitoreji esifanele sinweba impilo ye-I-jet spray nozzle nge-valve yokulawula. Amaqembu alandela lezi zinyathelo:

- Hlanza umlomo wombhobho kanye ne-valve yokulawula ngemva kokusetshenziswa ngakunye ukuze ususe izinsalela.

- Zomisa zonke izingxenye ngokuphelele ukuvimbela ukugqwala.

- Engeza i-antifreeze ezindaweni ezibandayo ukuze uvikele emonakalweni weqhwa.

- Gcina izinto zokusebenza endaweni eyomile, evalekile kude nezinambuzane kanye nomswakama.

- Hlola imibhobho namageji njalo, ushintshe izingxenye ezilimele ngokushesha.

Ukuhlolwa okujwayelekile kwama-valve okulawula kanye nezikali kuqinisekisa ukusebenza okuthembekile. Ukufaka izivikeli zegeji kusiza ukuvikela umonakalo. Le mikhuba igcina imishini yokucisha umlilo ilungele izimo eziphuthumayo futhi inciphisa izindleko zokuyilungisa.

Ukuhlolwa okuvamile, ukuhlanzwa, nokushintshwa ngesikhathi kwezingxenye ezigugile kugcina imibhobho ithembekile.

- Ukunakekelwa okungaguquki kwandisa impilo yesevisi, kunciphisa izinkinga zekhwalithi, futhi konga izindleko.

- Ukulungiswa kabusha nokuhlola kochwepheshe kuqinisekisa ukusebenza kahle nokushintsha ngokushesha.

Ukunakekelwa okungaguquki kuvimbela izinkinga futhi kuvikela ukutshalwa kwezimali kwemishini iminyaka.

FAQ

Amaqembu kufanele ahlanze kangaki i-Jet Spray Nozzle nge-Control Valve?

Amaqembu kufanelehlanza umlomongemva kokusetshenziswa ngakunye. Ukuhlanza njalo kuvimbela ama-clogs futhi kugcina iphethini yesifutho ingashintshi.

Yiziphi izimpawu ezibonisa ukuthi umlomo wombhobho udinga ukushintshwa?

Imifantu ebonakalayo, ukuvuza okuqhubekayo, noma iphethini yesifutho esontekile ibonisa ukuthi umlomo wombhobho udinga ukushintshwa. Amaqembu kufanele ahlole imishini njalo.

Ingabe amaqembu angasebenzisa noma yisiphi isisombululo sokuhlanza ku-nozzle?

Amaqembu kufanele asebenzise kuphela amanzi noma izihlanzi ezigunyazwe ngumkhiqizi. Amakhemikhali anokhahlo angase alimaze umzimba we-aluminium noma izingxenye zangaphakathi.

Isikhathi sokuthumela: Aug-25-2025